TMG Consultants

More experience. More performance. More than consultants. That is what we stand for. And that is how we measure ourselves. For more than 30 years, as a consulting company we have been focussing on solving complex management challenges in manufacturing industry companies – and convincing our customers based our wide-ranging technical expertise, cross-sector know-how – and even more with the people who work for us.

MORE THAN CONSULTANTS. FOR MORE THAN 30 YEARS

TMG CONSULTANTS – CONSULTING COMPANY FOR THE MANUFACTURING INDUSTRY

TMG is more.

COMBINED INDUSTRY, TECHNICAL AND PROBLEM-SOLVING EXPERTISE

Our activities focus on value-added processes and value enhancement for clients. Our consulting services are geared towards efficiency improvement programmes and their implementation, as well as projects that entail mastering complexity in innovation processes. We draw on our experience from almost 2,000 projects in various sectors and with companies of all sizes – from industrial groups and globally operating suppliers to ambitious medium-sized enterprises.

CONSULTING MUST PAY OFF.

SUSTAINABLE RESULTS

As problem solvers with a high level of industry-specific expertise, sound methodological knowledge and proven social and moderation skills, we are accustomed not only to developing forward-looking strategies and concepts with our clients, but also to implementing them quickly, in a results-oriented manner and in line with objectives. TMG consultants are used to “Pitching in.”

CONSULTING IS A MATTER OF TRUST.

CLIENT RELATIONSHIPS CHARACTERISED BY TRUST

Our long-term client relationships are characterised by mutual respect. We have maintained close partnerships with many clients for years. In joint project work, we design sustainable solutions, which we also implement in close cooperation.

Our consultants are personalities who bring their commitment and creativity to every single project. With profound specialist knowledge, a good portion of passion as well as high social competence, we succeed time and again in creating solutions that are not only accepted but also supported by the employees in the respective company.

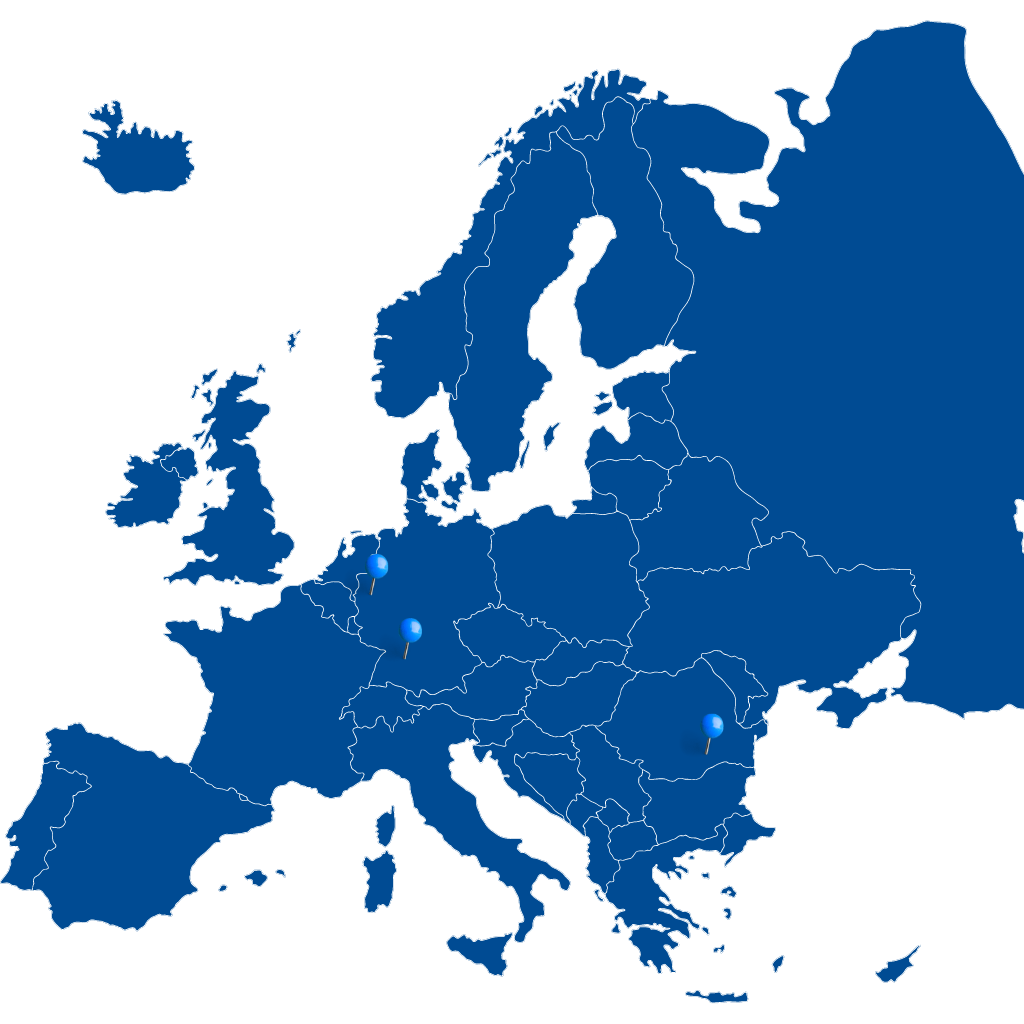

TMG REPRESENTED WORLDWIDE.

INTERNATIONAL NETWORK OF EXPERTS

By way of a selected network of experts and numerous project locations, we are present in the world’s most important industrial regions. Our strengths in consulting and dedicated country-specific know-how in important “Best cost countries” enable us to put together a range of services that makes us a sought-after partner in the industry for international tasks.

Another TMG asset is the very good relationships with political decision-makers, authorities and public institutions such as chambers of commerce and universities, some of which have existed for many years. Added to this is the ability of our staff and partners on the ground to deal with the specifics of each country in a target-oriented manner.

HEADQUARTERS STUTTGART

TMG Consultants GmbH

Schrempfstraße 9

70597 Stuttgart

Location Düsseldorf

TMG Consultants GmbH

Königsallee 27

40212 Düsseldorf

LOCATION BUCHAREST – ROMANIA

TMG Consultants Eastern Europe SRL

150th Uranus street, 5th District

3rd floor, office no. 7

050826 Bukarest

Romania