industries

The TMG consultants are able to understand complex interrelationships thanks to their expertise and enormous industry knowledge.

One of the most important industries

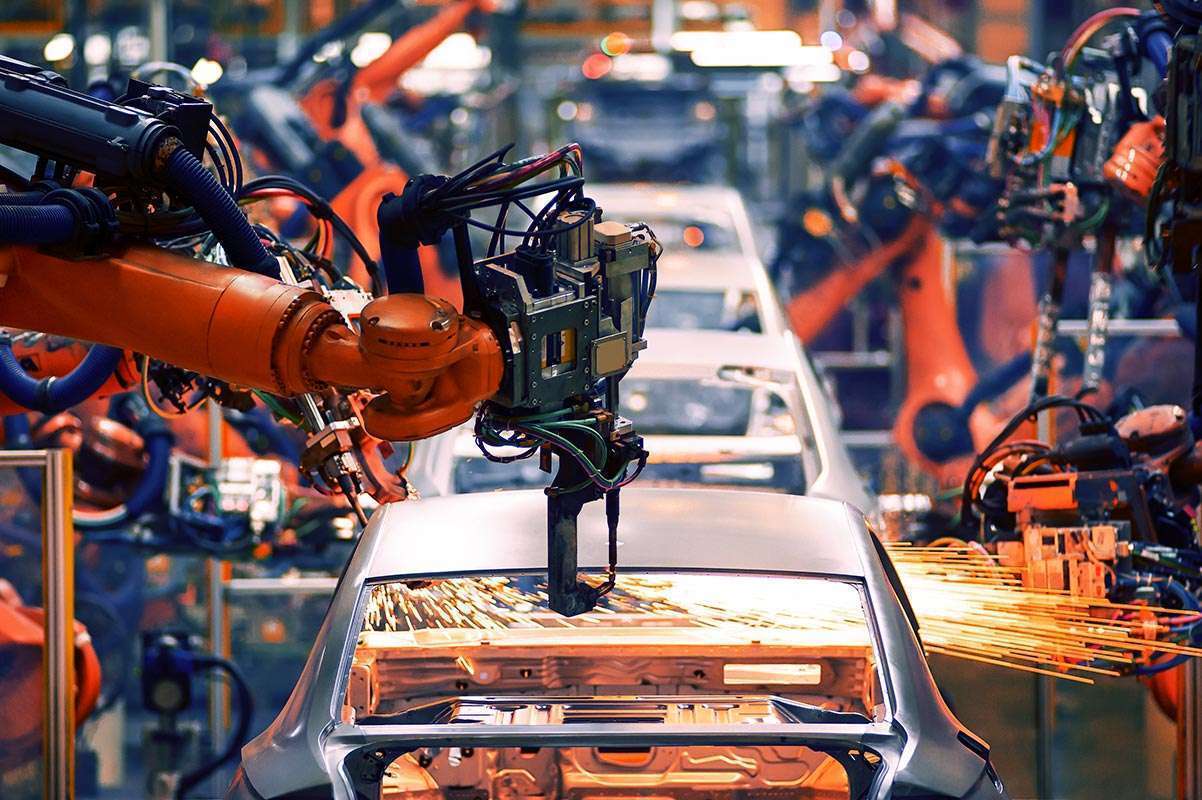

Automotive

The automotive industry is driven to structural change by technological, environmental and social mega trends. Topics such as reducing CO2 emissions, conversion to e-mobility, autonomous driving, new mobility concepts, networked vehicles, Industry 4.0 and additive manufacturing are aspects of the automotive sector more than ever before. These innovations are probably the biggest upheaval in the history of the automotive industry and require know-how and support.

A customised industry

Plant engineering

Companies in the plant engineering sector face an increasing number of challenges. Relying solely on quality, time and price as success factors will no longer be sufficient in the future. Additional assets are needed to remain successful and ward off the competition. Increasingly, these include HSE expertise, a professional plant service, in some cases also plant operation, dealing with export credit insurance and the qualified guarantee of “Local content” requirements.

One of the most innovative industries

Energy

Whether in the form of wind, water or solar power- renewable energies are shaping our future. Energy companies, plant manufacturers and their suppliers will also need to face this change. . At the same time, conventional technologies must be further developed. After all: Conventional energy sources will continue to find their markets abroad despite the dismantling of state guarantees.

More than transport and storage

Logistics

The logistics industry is facing a profound transformation and at the same time must master current challenges. These challenges must be embraced and changes translated into sustainable benefits. This includes the strategic to the operational level – from the first analysis to the realisation.

An industry in transition

Mechanical engineering

Mechanical engineering is one of the showcase industries of the German economy. With export quotas of constantly over 75% in recent years, this very medium-sized industry has always been forced to anticipate the developments and challenges of tomorrow and the day after tomorrow in a global context. Developing timely answers and strategies to remain successful and competitive is part of the daily practice of mechanical engineering companies.

The manufacturing industry

Process industry

The process industry is facing challenging tasks such as scarce raw materials, rising logistics costs, sales fluctuations and global markets with complex product structures. The challenges the process industry faces are manifold and will be overcome if companies succeed in achieving process excellence and sustainably improving their profitability. It is also already foreseeable that with the spread of Industry 4.0 solutions, companies will need to make further changes This is true, in particular, with regard to flexibilisation, modularisation or digitalisation of production.

Contactform

We Look Forward to Discussing Matters with You!

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information