NEXT LEVEL

EFFICIENCY

TMG Consultants is the go-to consulting company that will render your business even more efficient.

Our approach entails taking your strengths, processes and know-how to the next level of efficiency. We are convinced that with you we can make your company even more productive and, therefore, more successful.

Individual consulting

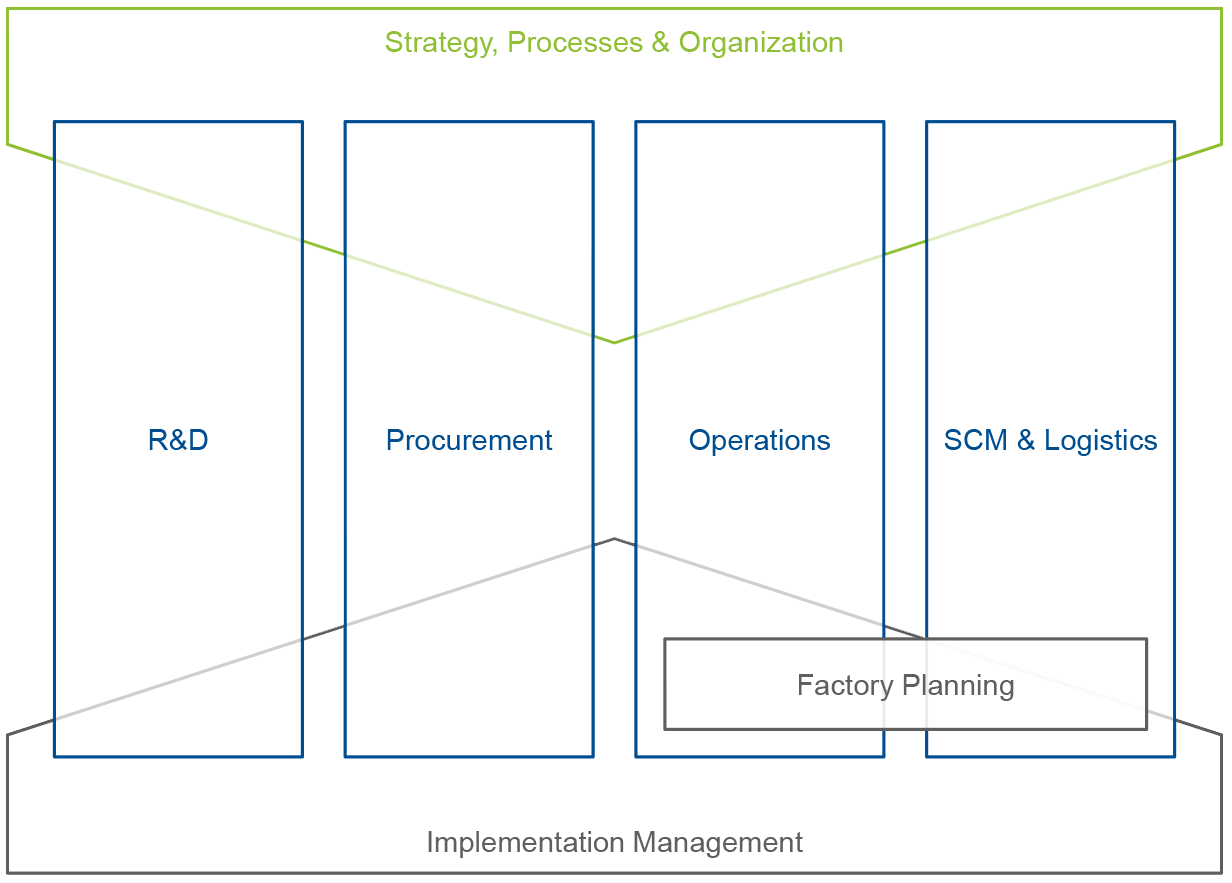

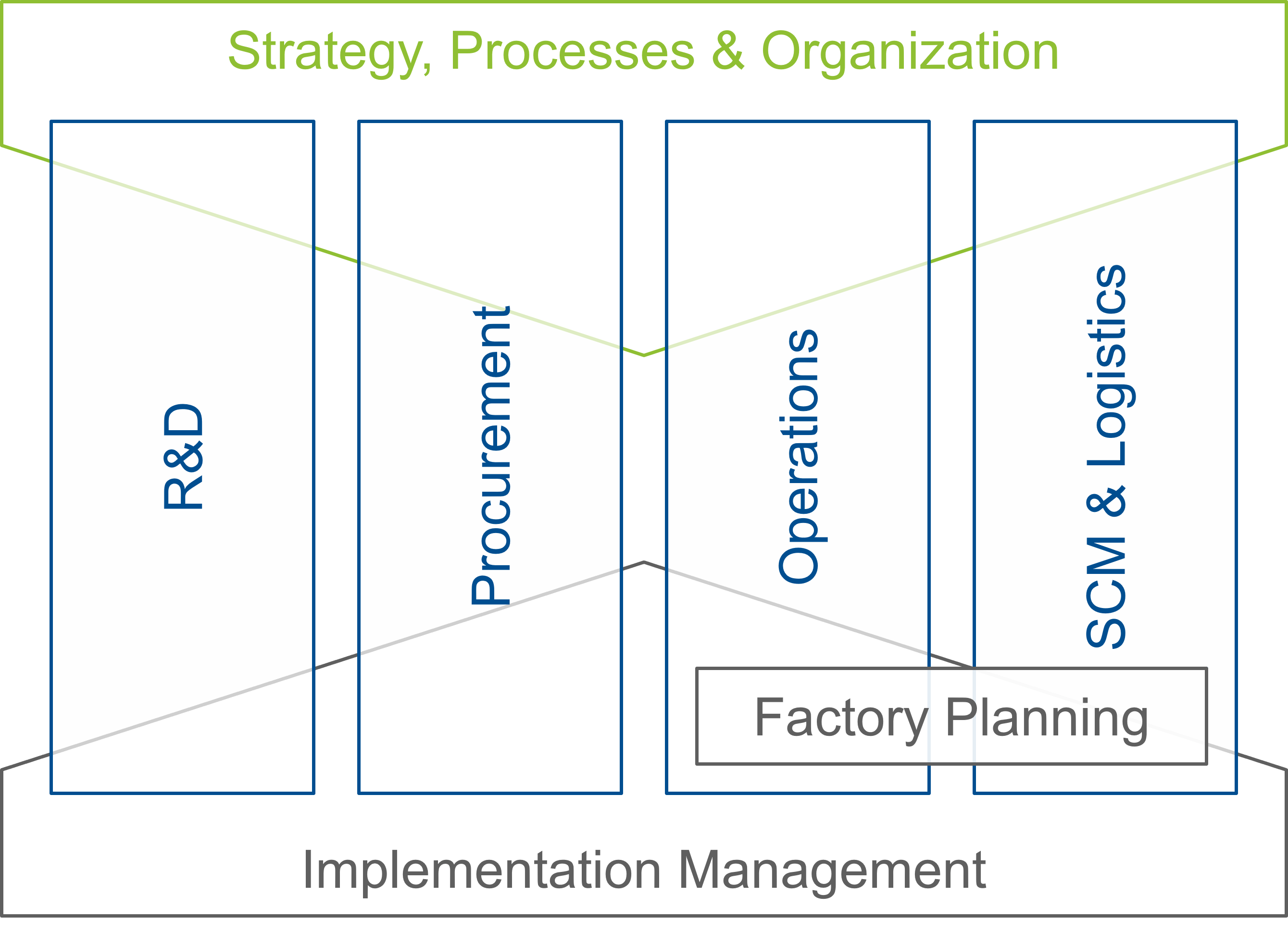

TMG Consultants: the Holistic Consultancy

For more than 30 years as a consulting company we have been focussing on the solution of complex management challenges in manufacturing industry companies. Our activities focus on value-added processes and value enhancement for our clients. Our results-oriented approach means our clients enjoy sustainable competitive advantages.

Sector-specific consulting

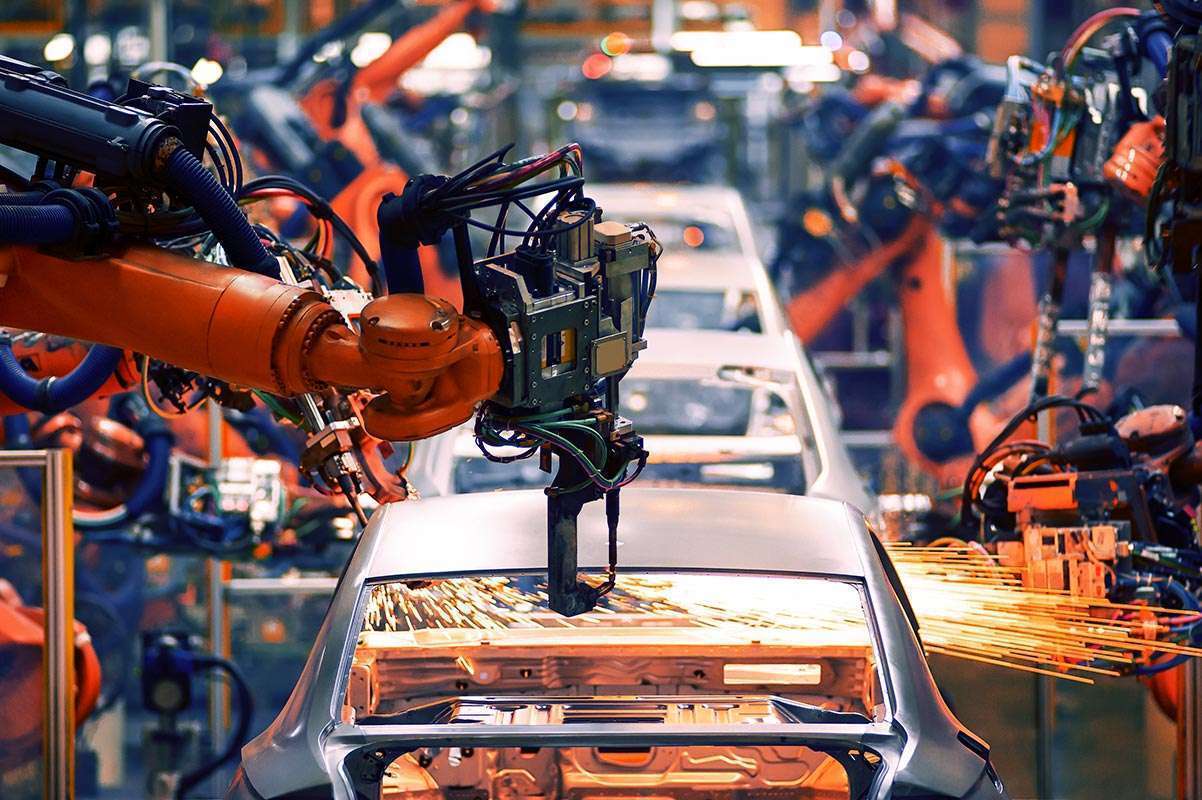

Our Industries

Facts & Figures

Satisfied customers

Projects

Years of company affiliation

Wealth of experience

Hidden Champions Awards

We want you

Working at TMG

If you want a career that is as distinctive as you are, then you’ve come to the right place. There is no up-or-out principle with us. We offer you a variety of challenging tasks and development prospects in a working environment characterised by a high level of performance orientation, a great deal of collegiality, plenty of creative freedom and an extremely family-friendly work-life balance.

Up to date

- Trends

KEY TO SUSTAINABILITY

CIRCULAR ECONOMY

The manufacturing industry’s answer to sustainability is the circular economy along its own value chain. TMG Consultants’ experience confirms that the fastest and most effective way to a more sustainable and yet economical business is based on the foundation of the circular economy.

Digitalisation

Migration to S4/HANA

Pressure to act arises: In 2027, the maintenance of the SAP R/3 system officially expires – SAP S/4HANA is coming! For medium-sized companies, this means that they have to deal intensively with a project in the top class of complexity and the associated risks. The fear of failure is great and justified in the German SME sector. Regularly, even large and experienced companies overestimate themselves when implementing such projects.

Your company even more efficient

EFFICIENCY INCREASE AND COST REDUCTION

All current economic forecasts and economic signs point in the direction of an economic slowdown. The Brexit discussion and the tariff and foreign trade disputes between the USA and China and the EU are also contributing to the fact that the manufacturing industry is looking forward to the coming quarters with a high degree of uncertainty and unanswered questions.